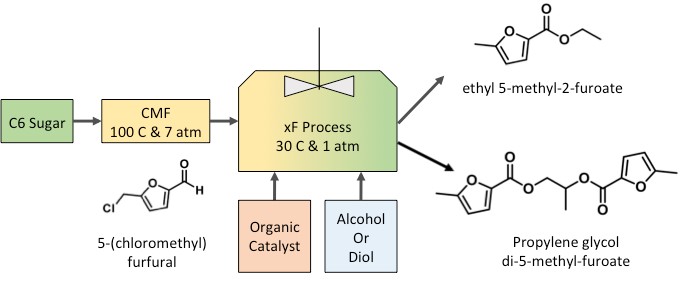

Our patented production process converts renewable materials like simple or complex sugars into safe and nontoxic renewable chemicals. It is a two-step, low cost thermochemical process that first generates a sugar derivative called CMF (5-chloromethyl furfural) followed by a catalytic step to convert the CMF into a finished product.

In the first step, hydrochloric acid (HCl) is used to break down the feedstock into C6 sugars that are subsequently converted into CMF. This reaction occurs via a non-catalytic proprietary process that operates at low-intermediate process temperatures.

The reactor effluent passes through a filter for the recovery of hydrothermal carbon (HTC), an effective soil amendment or an absorbent. After HTC removal, the two phases are separated into an aqueous and an organic phase:

- The aqueous phase is routed to an acid recovery unit where the acid is concentrated and pumped back into the CMF reactor. As a result of the acid concentration, a stream of potable water is generated.

- The organic phase contains the CMF as well as a solvent and is routed to a solvent recovery unit where the solvent is separated and recycled to the CMF reactor.

The concentrated CMF stream flows to a second vessel for conversion to the finished product via a catalytic process. The catalyst used belong to the family of N-Heterocyclic Carbenes (NHC). This type of catalysis was reserved until now for pharmaceuticals. Our patented process covers a novel and robust way to employ this little known catalysis at an industrial scale. One of the attractions of NHC catalysis as it is demonstrated through our process is that it allows the reaction to occur at near-room temperature and pressure. In turn, low-cost processing equipment can be utilized.

In addition to the CMF stream and the NHC catalyst, alcohol and base are added to complete the reaction. The effluent enters a filtration unit to remove any solids and the final 408 (or 408s if more than one alcohol is added) is purified as needed.

The proprietary organic NHC catalyst is manufactured and supplied by xF BioSolutions.

A simplified process flow diagram is shown below.