xF BioSolutions’ family of renewable products is manufactured using a novel catalytic process. Production CapEx and OpEx are cost advantaged versus petrochemical based analog products. This proprietary technology is protected by a series of issued and pending U.S. and international patents.

Important advantages of the proprietary production technology include:

- Biomass feedstock agnostic (compatible with cellulosic biomass, sugars and starches)

- Alcohol feedstock flexible (process utilizes ethanol, methanol, butanol, diols, polyols, etc)

- No carbon from feedstock is lost to CO2 during the conversion process

- Water and hydrothermal carbon are produced as co-products

- All chemicals used in the manufacturing process can be recycled

- Modest operating temperatures and pressures

The heart of xF BioSolutions’ process is the conversion of C6 sugars, in the form of cellulosic biomass, cornstarch, sugarcane or other renewable material, into a family of furoate molecules. This is done in two steps:

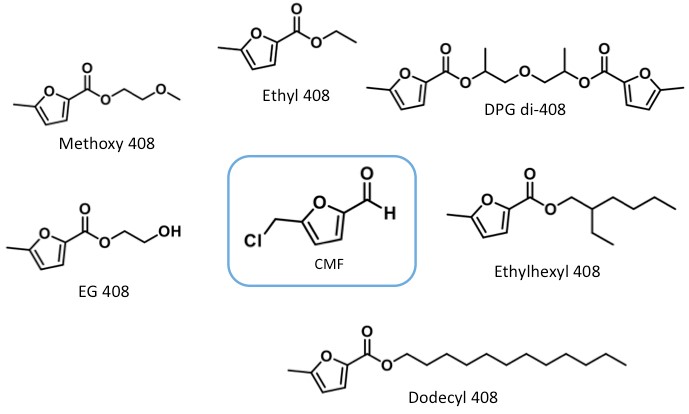

- C6 sugar bearing biomass is converted to a furan derivative, 5-chloromethyl furfural (CMF).

- CMF is reacted with alcohols or diols in the presence of a proprietary non-metallic catalyst, producing in the targeted product.

These molecules are trademarked as the 408™ family and was chosen since ‘408’ is phonetically very similar to ‘fur-o-ate’. xF BioSolutions’ process relates to a platform chemistry that can be used to produce a broad range of renewable chemicals serving many different markets and applications. Low cost of production is achieved through modest operating temperatures and pressures as well as extensive recycling of processing chemicals.

Illustrating the breadth of the platform, when CMF is reacted with an alcohol such as ethanol, a furoate ester (Ethyl 408) is created that is a powerful solvent. A second example is the reaction of a diol such as dipropylene glycol with CMF to create a furoate di-ester (DPG 408) that is a fast fusing plasticizer.

A few examples of what is possible are shown below: